Wilkes' Additive Manufacturing Lab is located inside the Mark Engineering Center on the first level of Stark Learning Center. It is designed to serve the needs of students, departments and programs of the Wilkes community. All members of the university community are encouraged to make use of this exciting technology.

Lab Details

The Additive Manufacturing Lab is a state-of-the-art facility dedicated to advancing research, innovation, and education through cutting-edge 3D printing technologies. This lab provides students, faculty, and researchers with hands-on access to industry-leading additive manufacturing equipment, fostering creativity and technological advancement across multiple disciplines.

Equipped with a diverse range of 3D printing technologies, including Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Stereolithography (SLA), and Digital Light Processing (DLP), the lab enables the fabrication of high-precision prototypes, complex geometries, and functional components. Additionally, a state-of-the-art 3D scanner enhances reverse engineering capabilities, allowing users to digitize physical objects for further innovation and optimization.

The Additive Manufacturing Lab plays a pivotal role in supporting interdisciplinary research and industry collaborations in fields such as biomedical engineering, materials science, aerospace, robotics, and product development. From designing patient-specific medical implants to developing next-generation antenna systems, the lab empowers students and faculty to push the boundaries of design, prototyping, and manufacturing.

By integrating hands-on learning opportunities with real-world applications, the lab prepares students for careers in advanced manufacturing, engineering, and technology-driven industries. Whether exploring innovative materials, refining digital fabrication techniques, or contributing to groundbreaking research, students and researchers at Wilkes University gain valuable experience in a rapidly evolving field.

The Additive Manufacturing Lab stands as a hub for creativity, exploration, and technological excellence, reinforcing our commitment to experiential learning and research-driven innovation.

Equipment

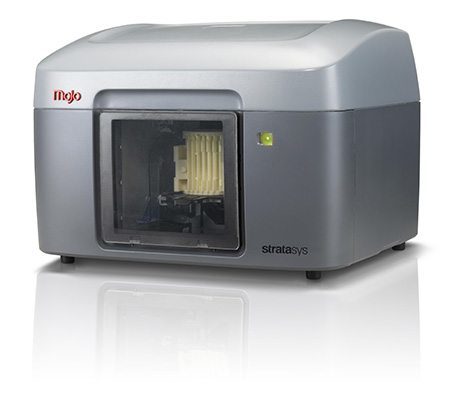

- Printing Process: FDM

- Build Size: 5 in. × 5 in. × 5 in.

- Materials: ABS and soluble support

- Description: A compact FDM (Fused Deposition Modeling) 3D printer with outstanding precision and reliability, making it ideal for prototyping and small-scale production.

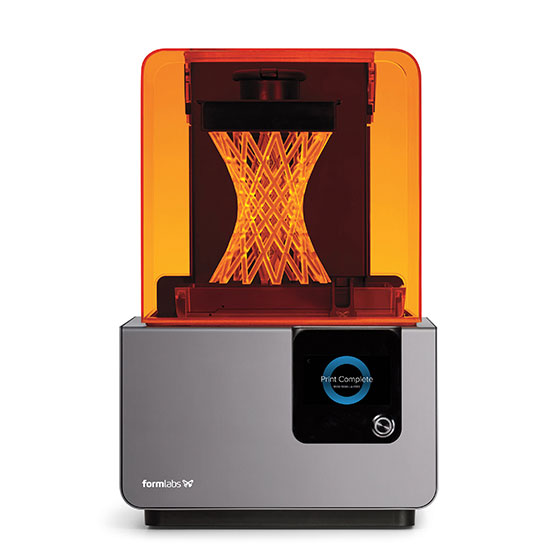

- Printing Process: SLA

- Build Size: 5 in. × 5 in. × 5 in.

- Materials: Photocurable Resin

- Description: A high-resolution SLA (Stereolithography) desktop printer that uses a laser to cure liquid resin into solid layers, producing intricate details suitable for prototypes.

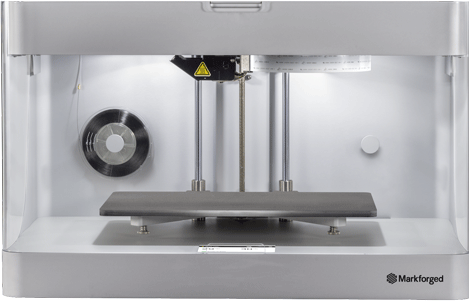

- Printing Process: FDM

- Build Size: 12.6 in. × 5.2 in. × 6 in.

- Materials: Onyx and Various Reinforced Fibers

- Description: A composite 3D printer that uses Continuous Filament Fabrication (CFF)

technology to print carbon fiber, fiberglass, and Kevlar-reinforced parts, making it ideal for functional prototypes and industrial applications.

- Printing Process: FDM

- Build Size: 7.76 in. × 7.76 in. × 14.76 in.

- Materials: PLA and ABS

- Description: A delta-style 3D printer with a large build volume that uses FDM technology and is known for fast printing speeds due to its design.

- Printing Process: SLS

- Build Size: 6.65 in. × 6.65 in. × 11.8 in.

- Materials: Nylon Powders

- Description: A compact SLS (Selective Laser Sintering) printer that creates durable, high-precision nylon parts by fusing powder materials with a laser, making it ideal for functional prototyping and small-batch manufacturing.

- Printing Process: FDM

- Build Size: 8.87 in. × 8.87 in. × 9.84 in.

- Materials: PLA and ABS

- Description: A user-friendly FDM printer that offers auto-bed leveling, making it accessible for beginners and hobbyists looking to create basic 3D prints.

- Printing Process: FDM

- Build Size: 11.8 in. × 11.8 in. × 15.7 in.

- Materials: PLA and ABS

- Description: A dual-extrusion FDM printer that allows users to print with two different materials or colors simultaneously.

- Printing Process: FDM

- Build Size: 13.8 in. × 13.8 in. × 15.7 in.

- Materials: PLA and ABS

- Description: A large-format FDM printer with solid frames, a bed-leveling sensor, and ability to print larger models.

- Printing Process: FDM

- Build Size: 7.87 in. × 6.69 in. × ∞ in.

- Materials: PLA and ABS

- Description: A unique FDM printer with a conveyor belt design that allows for continuous printing or creating long parts, making it ideal for batch production or long models that traditional printers can't accommodate.

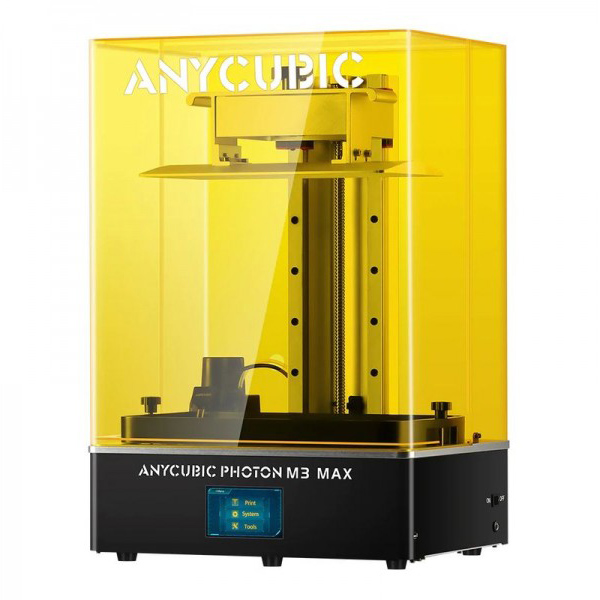

- Printing Process: LCD

- Build Size: 13 in. × 11.7 in. × 6.5 in.

- Materials: Photocurable Resin

- Description: A large-format LCD (Liquid Crystal Display) resin printer that is designed for high-precision 3D prints and is perfect for applications needing fine details.

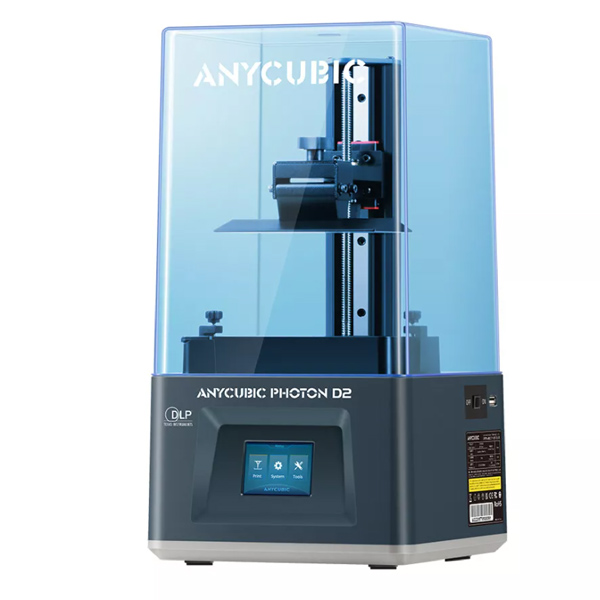

- Printing Process: DLP

- Build Size: 4.03 in. × 2.26 in. × 6.5 in.

- Materials: Photocurable Resin

- Description: A DLP (Digital Light Processing) resin printer that offers high resolution and smooth surfaces, providing faster print times and reduced maintenance.

- Light Source: Infrared

- Scan Rate: Up to 14 FPS

- Handheld: Yes

- Full Color Scanning: Yes

- Description: A handheld 3D scanner that captures high-quality scans for reverse engineering, 3D modeling, and prototyping.

3D Print Request Form